Production sites

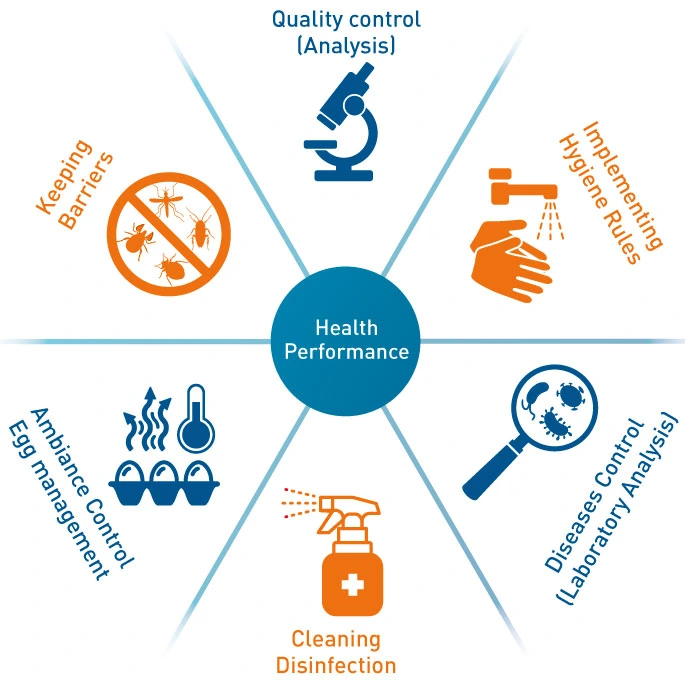

Combined with the use of thermally treated, safe feed, NOVOGEN implements rigorous biosecurity protocols at every stage of the production process: buildings, personnel movements, animals, and equipment.

The biosecurity

Beyond regulatory requirements, it is essential for multiplier customers that the animals supplied offer full traceability and excellent health status. NOVOGEN has always upheld high standards in terms of sanitary quality and biosecurity.

All our operations are overseen by veterinarians and follow strict monitoring protocols that go well beyond local regulations, regardless of the production site. NOVOGEN’s Quality and Veterinary Services ensure consistent health standards across all global sites.

We work closely with reference laboratories and veterinary experts and actively contribute to the development of sanitary regulations through strong partnerships with local veterinary authorities.

The quality

NOVOGEN’s quality strategy is built around four key pillars developed over the years:

- Guarantee and optimize the genetic potential of the animals distributed.

- Provide high-quality eggs and chicks, free from any health risks.

- Ensure consistent quality across all production sites.

- Secure a reliable and long-term supply for customers.

The Quality Department is responsible for implementing and monitoring biosecurity programs as well as continuous improvement plans deployed by all departments on a global scale.

The logistics

NOVOGEN implements specific measures to ensure full control of the air logistics chain:

- Exclusive use of freight forwarders specialized in live animal transport, with physical presence at the airport.

- Preferred partnerships with leading airlines.

- Training of handling agents at transit and destination airports.

- Support for customers with import and customs clearance procedures.

• “Known Consignor” (CCo) certification, issued by the European Civil Aviation Authority, ensuring cargo security from the point of departure.

For ground transport, NOVOGEN uses dedicated resources to ensure optimal conditions:

- Partnerships with carriers specialized in chick transportation.

- Driver training focused on NOVOGEN’s specific requirements in quality, biosecurity, and animal welfare.

- Strict monitoring of temperature, ventilation, and humidity throughout the journey.